Iron as a Transition element, Extraction of Iron Element,properties of iron

Iron as a Transition element, Extraction of Iron Element,properties of iron

- Electronic configuration of Iron : Fe26 [Ar18]4s2,3d6

- it is found in a form of ore about 6.3% in earth crust

- The is a compound of Iron with impurities

- Iron differs from the other previous metals in the First transition series GR?

- It does not reach to the maximum oxidation state that is (+8) which caused by the removal of all its 8 valence electrons from (4s and 3d)

- The most important oxidation states for iron are Fe2+ and Fe3+

- Iron is the most important metal in heavy industries

- Iron found in the form of pure iron (90%) in meteorites only

Bases of choosing the Iron ore to extract of IRON :

1- % of impurities and their type

2-Poisonous impurities as P, As, and s Sulphur and how to get rid of them

3-% of Fe in Ore

What are the IRON Ores:

1-Haematite Fe2O3 (IRON III oxide)-blood red– 50-60%Fe(ASWAN)

2-Limonite: 2Fe2O3.3H2O (Hydrated Iron III Oxide)-20-60%Fe(Oasis)

3-Magnetic Iron Oxide Fe3O4 black Iron Oxide Magnetic Iron oxide-45-70%Fe(East desert)

4-Siderite FeCO3 yellow grey ( Iron II carbonate)-30-42%Fe

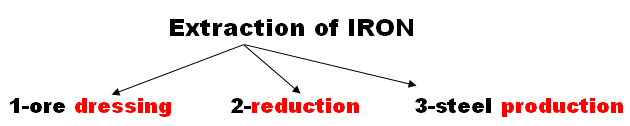

First : Dressing Ore:

1-ore dressing: by Crushing, sintering, concentrating, roasting

2-reduction: change the ore into Iron

3-steel production: to change the Iron(brittle) into steel Alloy (Iron and carbon which is more hardness )

What is the aim of ore dressing?

1)Improving physical properties :by crushing and sintering to get suitable size for reduction

1-crushing: to get ore with small size suitable for reduction

2-Sintering: collecting the iron ore particles getting from crushing or cleaning furnace in large size increase to be suitable for reduction

4-conentrating:

removing the unwanted impurities which chemically combined or mixed with ore by using surface tension property, magnetic or electrical separation

2)improving chemical properties: to get rid of impurities to increase Iron ore

How to improve the chemical properties?

By Roasting : heating of ore strongly in dry air to :

1)get rid of impurities by oxidation of (s) and (p)

2)expel humidity and

3)increase the % of Iron in Ore

a) expelling CO2 from the ore:

b)Expelling Humidity (H2O)

2Fe2O3.3H2O (40%) ⇒ 2Fe2O3 (69.6%) + 3H2O

c)oxidation of some impurities (S ,P)

1)Sulphur: S(s) + O2(g) ⇒ SO2(g)

2)phosphorous: 4P(s)+ 5SO2(g) ⇒ 2 P2O5 (g)

Second: reduction of IORN ore : by one of the 2 methods

The Iron produced from the furnace is so brittle and cannot use in industry

Third: steel production:

By 1)removing impurities resulted from furnace

2)Adding desirable element to get steel with desirable properties

That are done through 3 process: in 3 furnaces

1)electric furnace 2) open hearth furnace 3) oxygen converter

Properties of IRON 1) physical 2)chemical

1)Physical properties:

-Pure iron has no industrial importance GR?

Because it is relatively soft,low hardness malleable and ductile and has magnetic properties

-it melts at 1538 c ,it density is 7.87 gm/cm3

2)chemical properties of iron:

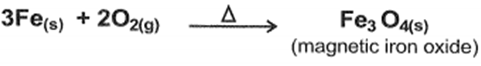

1)effect of air in iron: Red hot iron reacts with dry air(O2) giving magnetic iron oxide

2)effect of water :red iron hot react with water vapor giving magnetic iron oxide and hydrogen

3)reaction with non- metals : iron react with chlorine gas giving iron(III)chloride(as chlorine is a strong oxidizing agent )

4) iron react with Sulphur giving iron(II) sulphide (as sulphur is a weak oxidizing agent)

5)Reaction with acids :

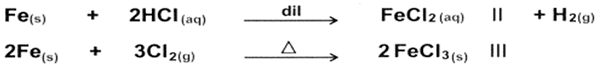

a)with diluted acids: Iron dissolves in dilute acids to form iron (II) salts and hydrogen GR?

-because hydrogen gas is reducing agent prevent formation of iron(III) salts:

b)with concentrated acids:–

Iron reacts with hot concentrated sulphuric acid to give :

Iron(II)sulphate ,iron(III) sulphate ,water and Sulphur dioxide gas:

G.R: Concentrated nitric acid HNO3 has a passivity effect on the iron ?

-Due to the formation of a non-porous layer of iron oxide which protects the metal from further reaction

-This layer can be removed by abrasion or by dilute hydrochloric acid HCl

-How can you convert iron metal into FeCl2 and FeCl3?

-How can you detect for Fe2+ and Fe3+?

Question: How can you get iron(II) hydroxide and iron(III)hydroxide